We are happy to welcome you here. Please provide the below information and we shall contact you at ealiest. you can also send us direct email to the email address given below.

Email : info@rihongfa.com

Other Websites:

www.rijapaninfra.com

A part of the Rising Hongfa Group

www.risinghongfa.com

The RSHZ series concrete mixing plant is an automatic

concrete mixing assembly consisting of batching, mixing

and computerized control system. Equipped with high-

precision microcomputer control and separate manual

control, the plant has features for batch mixing memory,

automatic drop compensation and sandstone moisture content

compensation. This withprinting system gives highly automatic

production of commercial readymixed concrete saving lot of

time and money.

The RSHZ series concrete mixing plant is an automatic

concrete mixing assembly consisting of batching, mixing

and computerized control system. Equipped with high-

precision microcomputer control and separate manual

control, the plant has features for batch mixing memory,

automatic drop compensation and sandstone moisture content

compensation. This withprinting system gives highly automatic

production of commercial readymixed concrete saving lot of

time and money.

Used as storage and automatic release of dry material like

cement, sand fly ash etc. This attached with screw belt conveyor

woks for automatic feeder. With vibrating discharge mechanism

and auto-release system this is most convenient, economical

and money saving. It makes the working environment friendly

and also saves lot of space. Rising Hongfa has designed and

produced chip form cement silo, to save cargo space and costs.

It comes in different sizes and capacity.

Used as storage and automatic release of dry material like

cement, sand fly ash etc. This attached with screw belt conveyor

woks for automatic feeder. With vibrating discharge mechanism

and auto-release system this is most convenient, economical

and money saving. It makes the working environment friendly

and also saves lot of space. Rising Hongfa has designed and

produced chip form cement silo, to save cargo space and costs.

It comes in different sizes and capacity.

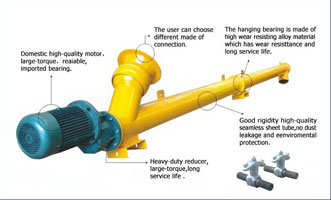

Rising Hongfa screw conveyor is a rotating helical screw blade system in steel tube used for bulk handling of dry, semi-solid and slurry material horizontally or at a slight incline as an efficient way to move and feeding of material. Our screw conveyor uses tough motor sysem with sealed protection for longer life and it is an integral part of plant fixed at different places from silos to the feeding hopers to molds. It is made of high-quality steel pipe with good integral rigidity. With high-quality reducer and heavy-design it has the advantages of large torque low noise no dust leakage long service life.The design of double pitch for reducing the compress extent of the material in transportation is especially suitable for long-distance transportation of cement and other powder materials. Large stock for common diameter of 219273and dimension & angle can be customized according to your need. It has different capacities and models. Please contact us for further information.

Rising Hongfa screw conveyor is a rotating helical screw blade system in steel tube used for bulk handling of dry, semi-solid and slurry material horizontally or at a slight incline as an efficient way to move and feeding of material. Our screw conveyor uses tough motor sysem with sealed protection for longer life and it is an integral part of plant fixed at different places from silos to the feeding hopers to molds. It is made of high-quality steel pipe with good integral rigidity. With high-quality reducer and heavy-design it has the advantages of large torque low noise no dust leakage long service life.The design of double pitch for reducing the compress extent of the material in transportation is especially suitable for long-distance transportation of cement and other powder materials. Large stock for common diameter of 219273and dimension & angle can be customized according to your need. It has different capacities and models. Please contact us for further information.

RISING Hongfa materials batching machine PLD series has

detachable structure, which makes it easy to be fed. It can

batch several kinds of materials automatically according to

the mixture ratio set by users. Electric weighing with a sensor

has advantages of accurate weighing and precise batching.

Strong microcomputer control system makes it easy for users to

Operate with just one key. A cover at the top of belt machine prevents

spilling effectively. Easy to clean, maintain and service. It is convenient

for moving and installation and has many models.

RISING Hongfa materials batching machine PLD series has

detachable structure, which makes it easy to be fed. It can

batch several kinds of materials automatically according to

the mixture ratio set by users. Electric weighing with a sensor

has advantages of accurate weighing and precise batching.

Strong microcomputer control system makes it easy for users to

Operate with just one key. A cover at the top of belt machine prevents

spilling effectively. Easy to clean, maintain and service. It is convenient

for moving and installation and has many models.

Rising Hongfa JS series twine shaft forced concrete mixer is an ideal material

mixing unit for concrete batching plant, with the advantages of highly automatic

operation, excellent mixing quality, high efficiency, low energy consumption,

low noise pollution, easy handle and maintenance.

Rising Hongfa JS series twine shaft forced concrete mixer is an ideal material

mixing unit for concrete batching plant, with the advantages of highly automatic

operation, excellent mixing quality, high efficiency, low energy consumption,

low noise pollution, easy handle and maintenance.

As a professional manufacturer and supplier of stationary concrete batching

plants our company has focused on the creation and innovation of stationary

concrete batch plant for years. Our machine has the advantages of high quality

reasonable price good performance and long service life. Up to now our machine

has sold very well at home and abroad and we have varieties of stationary concrete

batch plants for sale to meet your different requirements.

The plant is controlled by centralized Intelligent computer control. All activities are

Pre feed as per the batch requirement and thereafter the operation is taken over

by the control system. We use top quality components made by world famous

electronic companies like Schneider Electronics, SIEMENS and TI of USA

These reliable components enable the controlling system with stable and high

working efficiency.Advanced printing and monitoring system guarantees the

smooth and efficient daily production. It is worth investing in the system to make

working smooth and economical.

The plant is controlled by centralized Intelligent computer control. All activities are

Pre feed as per the batch requirement and thereafter the operation is taken over

by the control system. We use top quality components made by world famous

electronic companies like Schneider Electronics, SIEMENS and TI of USA

These reliable components enable the controlling system with stable and high

working efficiency.Advanced printing and monitoring system guarantees the

smooth and efficient daily production. It is worth investing in the system to make

working smooth and economical.